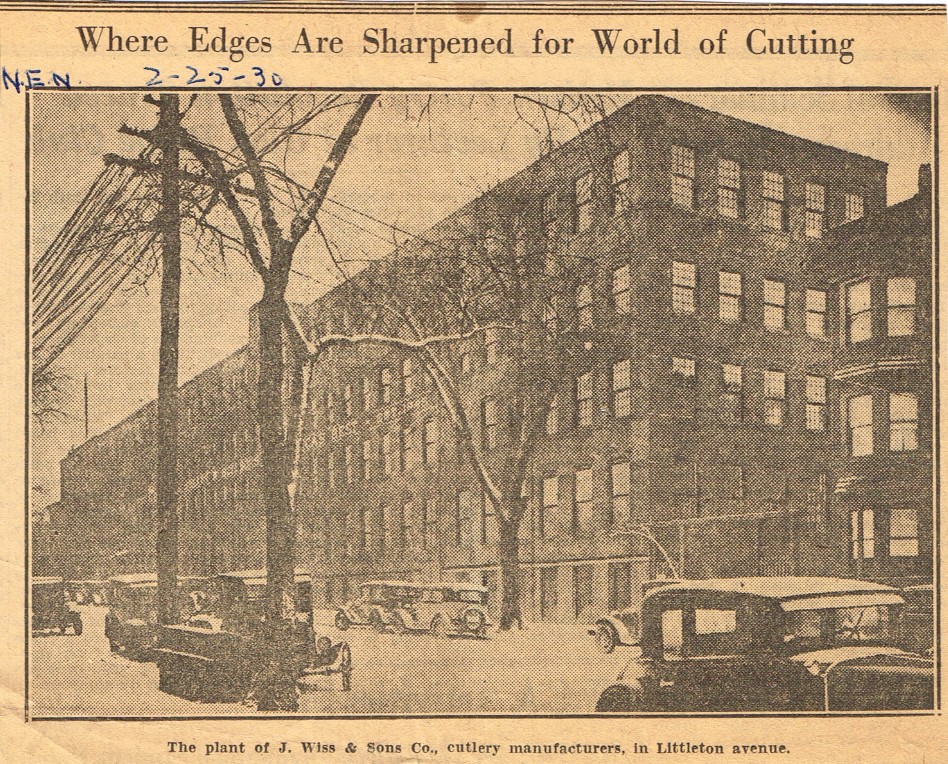

Where Edges Are Sharpened for World of Cutting

Reaching out to all corners of the world steel cutting edges forged in the Littleton avenue plant of J. Wiss & Sons Co. establish part of Newark industry on an intimate international plane. Shears and other cutting implements made in the factory are to be found in homes, hospitals and other institutions, in fruit orchards, vineyards cattle ranches and the shops of tinsmiths, tailors and countless tradesmen.

Since the first pair of shears was ground out eighty-two years ago in an old stable in Bank street on the site now occupied by part of the Prudential building the late Jacob Wiss and his children have built a business with annual production well into seven figures. The first shears were ground with a dog training power. Now skilled workers grind out the articles on electrically-powered stones and belts.

The details of some processes of manufacture notably involving use of razor steel and stainless steel, are secretive, only picked men being permitted to work in their production.

The Wiss plant covers the major portion of the block from Warren street to Eleventh avenue and Littleton avenue to South Sixth street. It comprises two strings of four-story structures, combined and modernized.

All the employees are on piece work. Few glance up from their labor as a stranger passes. The inspection crew is paid partly on a basis of the number of errors in manufacture it detects. These principles were handed down from the founder.

There are many uses for the plant's products. Recently the company outfitted an expedition of explorers going into British New Guinea. A batch of barbers' shears have been sent to the bushmen in Australia. A Japanese visitor took home a pair of shears for his personal barber. The products, according to the sales records, have gone to every country.

Wiss shears have been adopted as standards by the United States and California Fruit Growers' Associations and the Florida Citrus Growers' Association.

Shears with roller attachment for cutting messages from machines in telegraph offices are manufactured for the American Telegraph & Telephone Co. Special implements for surgical and industrial uses are made in a wide assessment.

The company maintains a museum of old goods, including a pair of tailoring shears made by Wiss seventy-five years ago and found in the basement of a Brooklyn building and shears which had been given by Mrs. Jacob Wiss as a wedding gift to a friend forty-four years ago.

Frederick C. J. Wiss, son of the founder, is president of the company. His sons, J. Robert and Norman, are executives. Frederick H. Rauh Jr., factory manager, succeeded his father, now dead, eighteen years ago. William Marshall has been in the finishing department twenty-six years, succeeding fifteen years ago to the special job his father held before him.

C.L. Gairoard, salesmanager, at one time was the company's sole salesman. He has been connected with the concern thirty-seven years, first appearing in the plant as an agent for a nation wide distribution organization, now defunct, with which the Wiss firm had become partially affiliated.

Four of the employees have been with the company more than a half-century. Edward Startzar has been a polisher fifty-eight years, and the others are George Ott, Charles Lambineus and Al Lehman. Nineteen employees have been in the plant thirty-five years or more.